Not all profiles are alike. The basic material used for curing chambers by HS Anlagentechnik is a specially galvanised steel strip, which is manufactured on the basis of DIN EN ISO 9002 (EU origin) for all load bearing system elements. Top quality is offered by a pure galvanised anti-corrosion layer at least 70 μm thick.

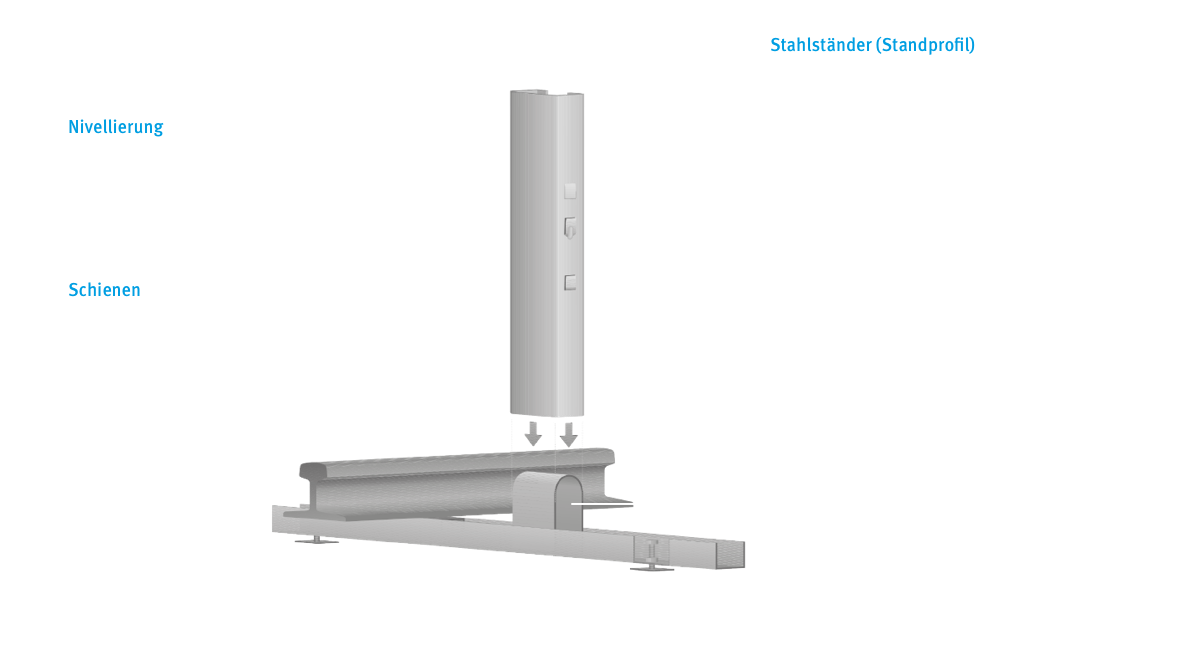

The steel posts (upright profiles) are cold rolled from specially galvanised steel strip and offer a high dimensional accuracy. The C profile, measuring 100 to 200 mm (width) x 50/70 mm (depth) x 3 mm (material thickness), not only has a high section modulus, but also the stability necessary to be able to support ceiling or roof structures (in use for loads of 400 kg/m2).

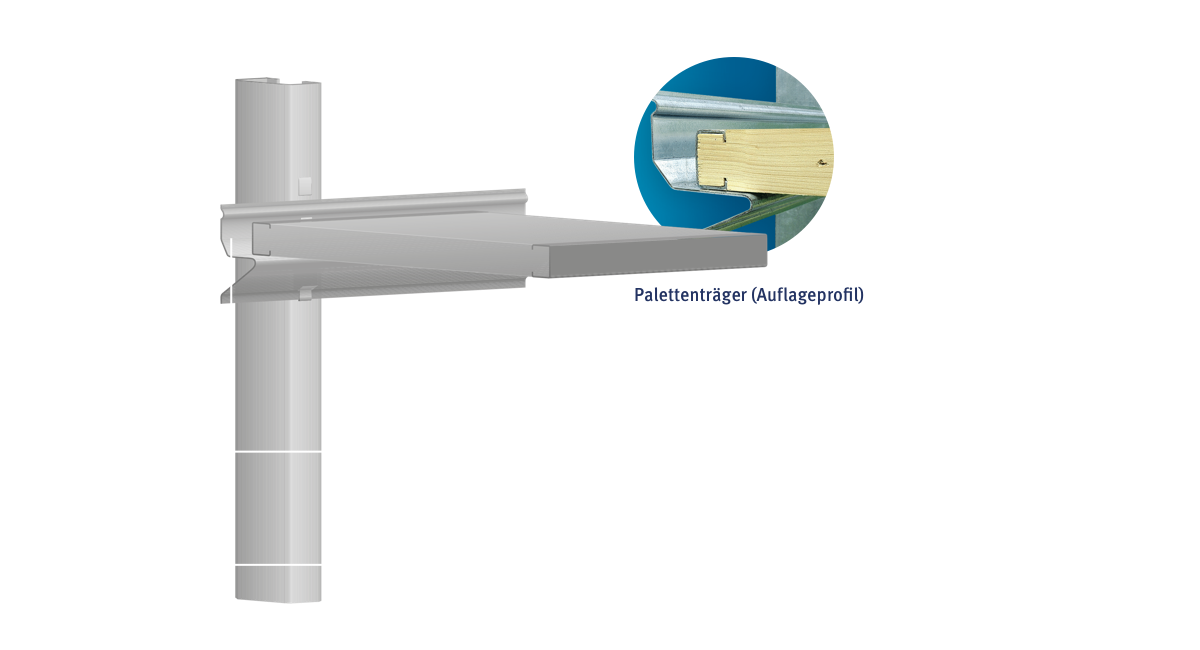

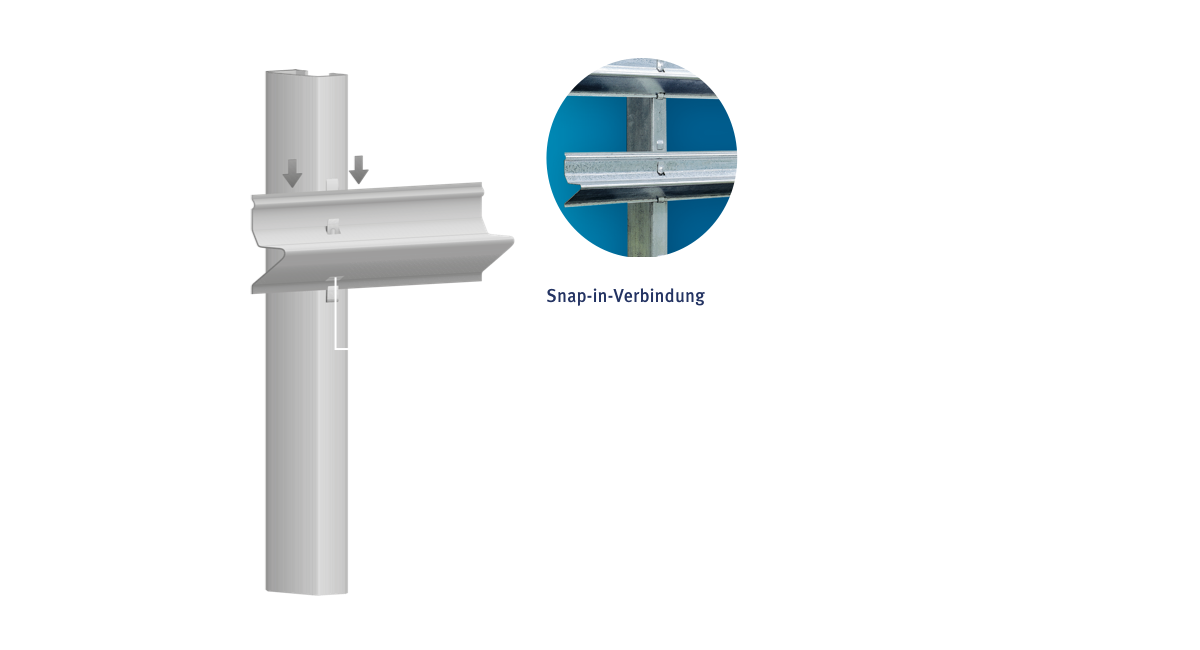

The steel strip for the support profiles is similarly cold rolled in a profiling facility and is given the contour that makes the snap-in connection possible, with all of its structural advantages in the finished rack. The pallet supports are manufactured in lengths of up to 9 m and each of them has the same total length as an assembly.

The TÜV has recognised that too!

The load capacity of the pallet supports with snap-in connection has been tested by the TÜV. The test report confirms that the required load capacity of the support profile is safely ensured.

'Just insert, press downwards – and the post and support profiles are fixed permanently to one another. The steel parts latch precisely with one another to the exact millimetre. This ideal snap-in connection gives rise to one advantage after another: Saving of time due to the simplest possible assembly. Extreme rigidity of the curing chambers allows maximum static loading and highest load capacities. Technology that means cost reduction and production safety – technology for professionals.'

Capacity and planning made to measure

HS Anlagentechnik supplies curing chambers in a building kit system. 2 to 5 chamber lanes are assembled together in a frame construction mode and combined with one another.

Two, three, four and five-chamber combinations

E.g. if 10 chamber lanes are required, these can be made up of two 5-chamber combinations or two 4-chamber combinations and one 2-chamber combination. The number of storage spaces can be planned individually and easily expanded.

Each of these assemblies is a self contained, absolutely solid unit with an inherent structural stability. The biggest advantage of this is that curing chambers by HS Anlagentechnik can always be constructed freestanding. They do not need to be braced laterally or upwardly. Greater safety for heavily loaded storage systems that are continuously in operation.

The chamber system and the snapin-connections offer the best conditions for fast, safe assembly or selfassembly and, hence, a saving on costs. Our assembly instructions provide valuable help here.